The underground coal mining industry, crucial for steel production and power generation, faces one of its most significant hazards in the form of coal dust explosions. Despite its long history, effective management of explosive dust remains a challenge. Research has highlighted the stagnant state of explosive dust management, with minimal progress over nearly a century.

The Challenge

Traditional methods of managing stone dust, an incombustible material crucial for mitigating coal dust explosions, have several drawbacks:

- Delayed and Inaccurate Information: Slow, disconnected, and manual processes result in delayed and often inaccurate data.

- Limited Visibility and Proactive Measures: There’s a lack of visibility into compliance and explosion risk, leading to reactive rather than proactive management.

- Delayed Reactions to Failures: Failures in dust management are often not identified or addressed in a timely manner, increasing the risk of explosions.

Limited Visibility and Delayed Reaction to Failures.

End-to-End Explosive Dust Management Solution

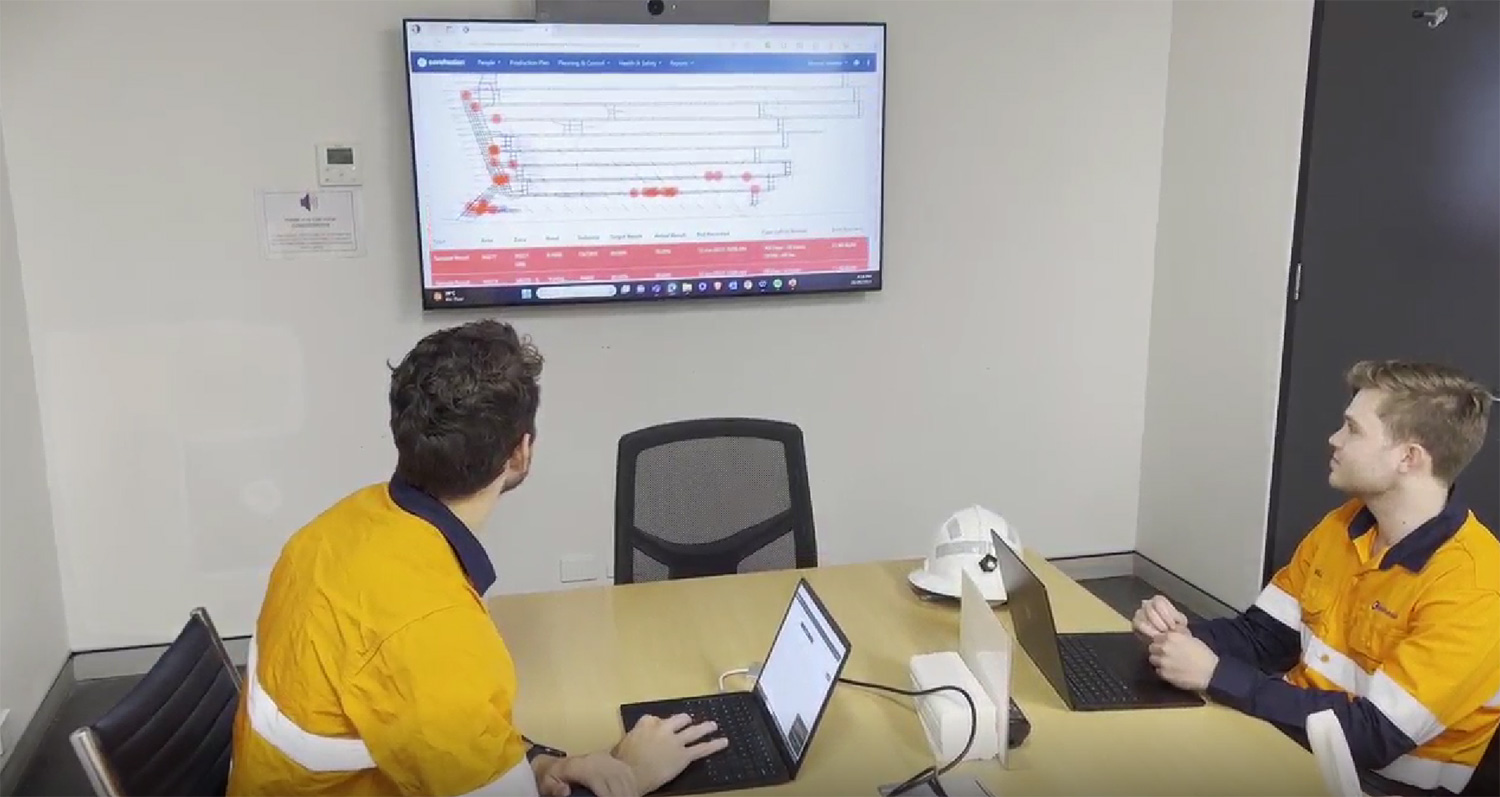

Corehesion has developed an innovative solution to these challenges, integrating cloud and mobile technologies with business intelligence (BI) and a portable mid-infrared spectroscopic device to revolutionize explosive dust management in underground coal mines.

- Reduced Risk of Coal Dust Explosions: reduced safety risk through improved timeliness and reliability of stone dust application, sample, analysis and failure response.

- Assured Compliance: The system ensures adherence to regulatory standards with complete and accurate records of your explosive dust management procedures.

- Cost Savings: avoid the cost of third-party laboratory services, reduce the amount of re-dusting, reduce the cost of labour on administrative and information processing tasks.

Corehesion’s Digital Twin and Real-time Failure Data

Key Features and Benefits:

- Digital Capture of Stone Dust Application: Using intrinsically safe tablets, workers can capture data on the amount and location of stone dust applied in real-time, ensuring accurate and timely records.

- Streamlined Sampling Processes: Explosive dust zones and their sampling requirements are integrated ensuring samples are taken on time, with less errors and are easily tracked.

- Live Integration and Feedback: Integrated directly with the laboratory for sample result data for accurate and timely feedback on failures or a portable mid-infrared spectroscopic device for immediate on-site analysis and feedback.

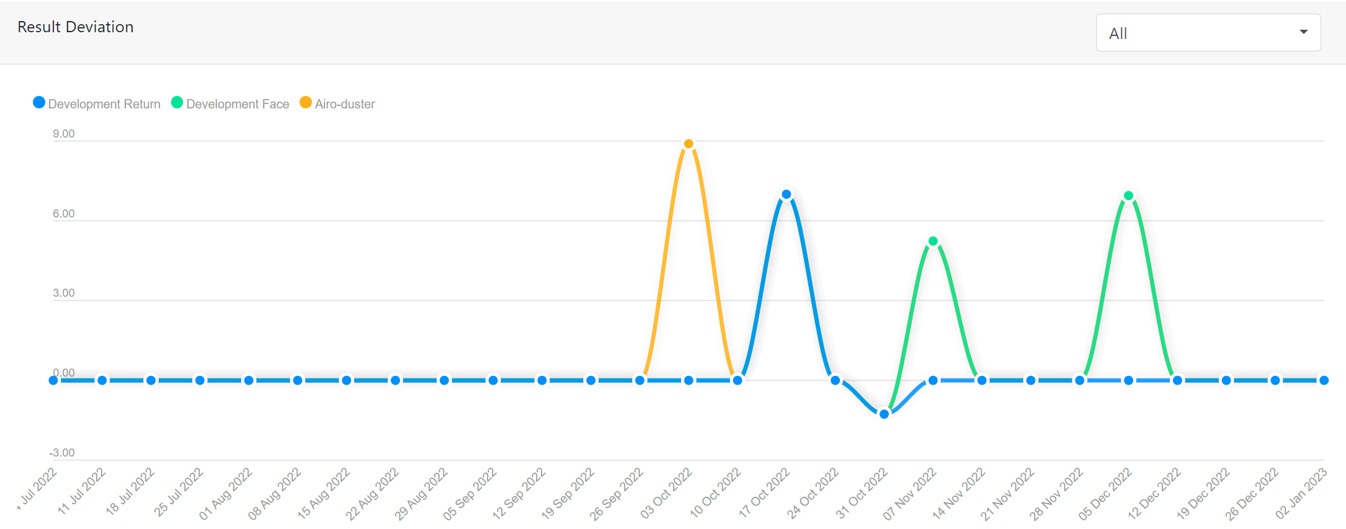

- Live Failure Mapping: A digital twin mine map displays real-time failure data, enabling quick identification and rectification of issues.

- Optimized Dust Application Rates: BI tools optimise the stone dust application rate, avoiding over or under-dusting and saving time and resources.

On-site Sample Analysis (Portable Mid-infrared Spectroscopic)

The Role of Business Intelligence

BI plays a pivotal role in Corehesion’s solution, providing a data-driven approach to enhance safety and efficiency. Key components include:

- Data Warehouse: A centralised repository consolidates data from various sources, ensuring reliability and usability.

- Descriptive and Diagnostic Analytics: These analytics provide insights into past events and uncover relationships and patterns in the data.

- Predictive and Prescriptive Analytics: These advanced analytics forecast future events and prescribe actions to achieve desired outcomes.

- Analytical Dashboards: Real-time dashboards offer visual representations of data, facilitating informed decision-making.

Compliance Deviation

A Proven Solution

By integrating innovative technologies and data-driven decision-making, Corehesion is setting new standards in mining safety and efficiency. For more information and to see a live demonstration of our solutions please contact us.